ABOUT US

-

40+R&D Personnel

-

41ItemsPatent

-

6ItemsInvention Patent

-

200Thousand m²Car making workshop

company

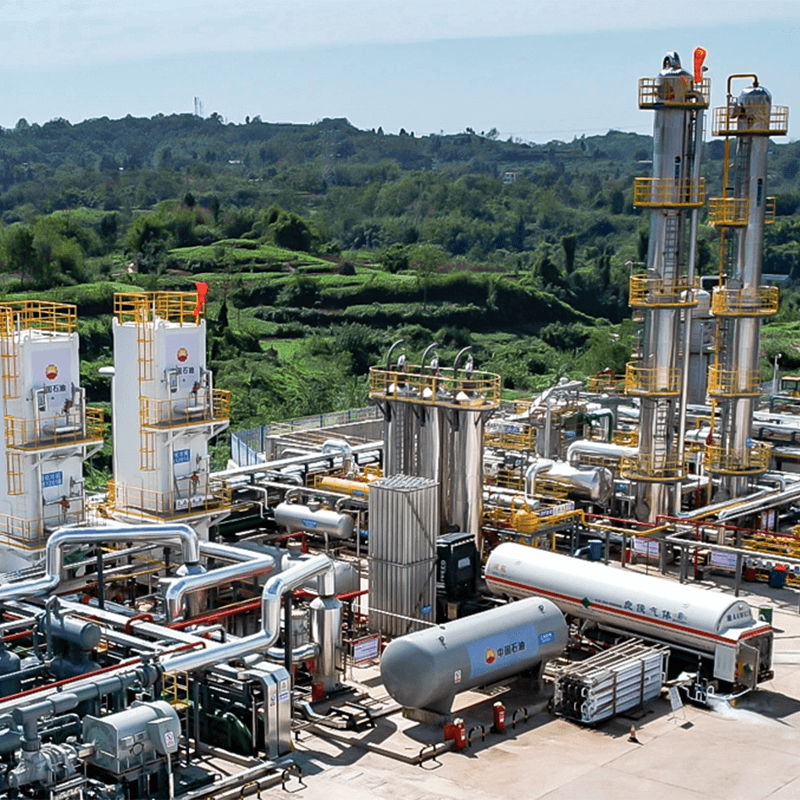

ADVANTAGES

By providing customers with high-quality, efficient and satisfactory services, we are not only renowned in Chinese market, but also play an important role in the international market.

● 20+ years in natural gas treatment

● Experienced staff

● Strong R&D capability

Professional design team

Our Spirit, Elaboration, dedication, pragmatism and innovation.

Strong production strength

Our Value, Simplicity and harmony, honesty and integrity, loyalty and affection, win forever.

Advanced production equipment

Our Vision, To be the leading manufacturer in oil and gas industry in China.

Perfect service system

Experienced engineers keep eyes on cutting-edge technology of natural gas treatment.

Our 120 million Nm3/d tail gas treatm...

Natural gas exhaust treatment is an important part of the natural gas industry, aimed at reducing the emission of harmful substances in exhaust gas, protecting the environment and human health. The natural gas purification plant adopts advanced tail gas treatment technology to ensure that toxic and harmful substances in the tail gas are completely oxidized before being discharged, in order to meet pollutant emission standards and avoid air pollution. Here are some key processing methods and technical applications.

Natural gas processing process for r...

Natural gas processing is the process of removing water vapor, hydrogen sulfide, mercaptan, and carbon dioxide from natural gas. The main equipment includes dehydration unit, desulfurization unit, decarbonization unit, and light hydrocarbon recovery unit.

Understanding the Different Processes...

In addition to absorption and adsorption, membrane dehydration unit is gaining popularity in natural gas dehydration plants. This process involves using semi-permeable membranes to selectively remove water vapor from the gas stream. The membranes allow water molecules to pass through while retaining the dry gas. Membrane dehydration is known for its simplicity, compact footprint, and low energy consumption. It is particularly suitable for small-scale gas processing operations and applications where space and energy efficiency are critical. However, membrane dehydration may not be as effective in achieving extremely low water content levels compared to absorption and adsorption methods.