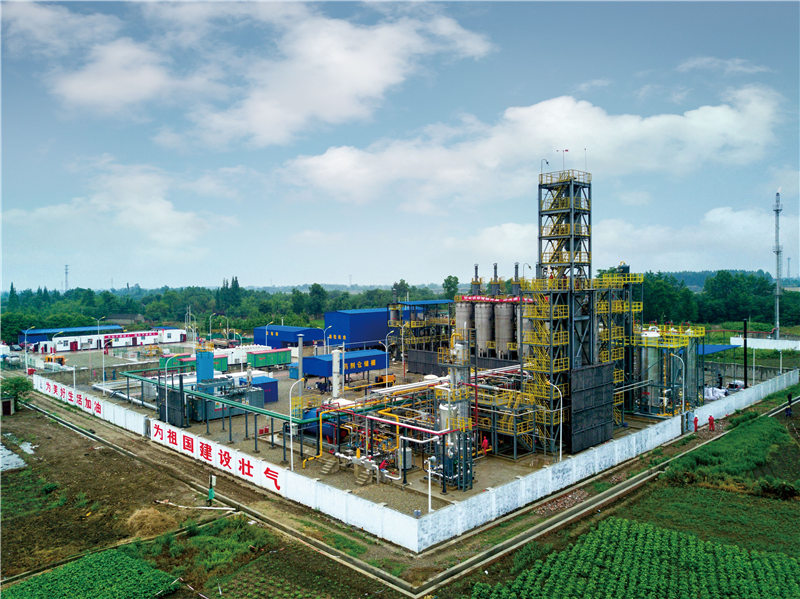

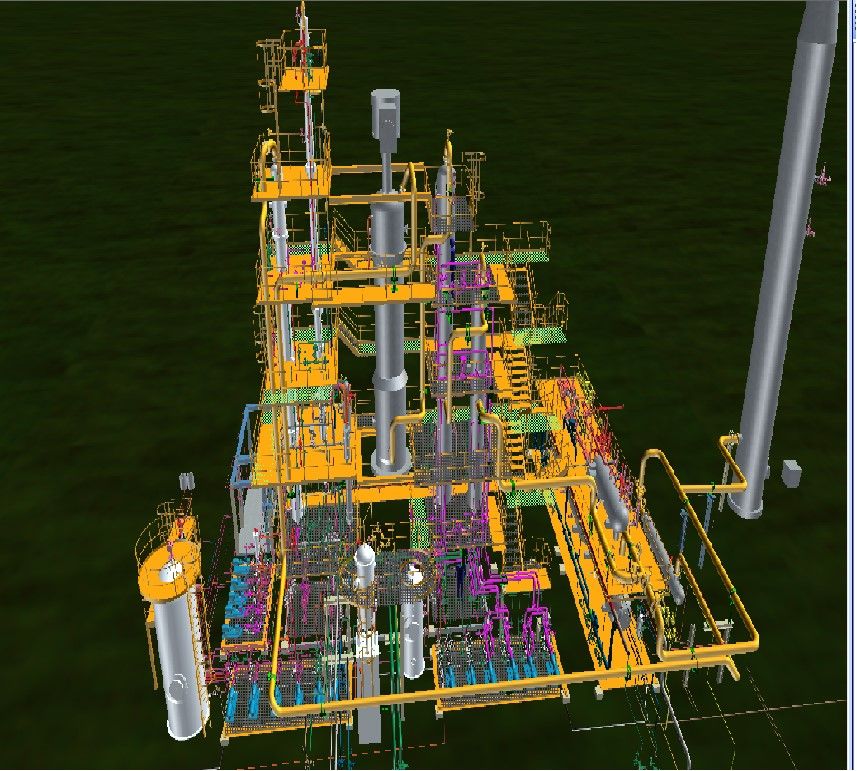

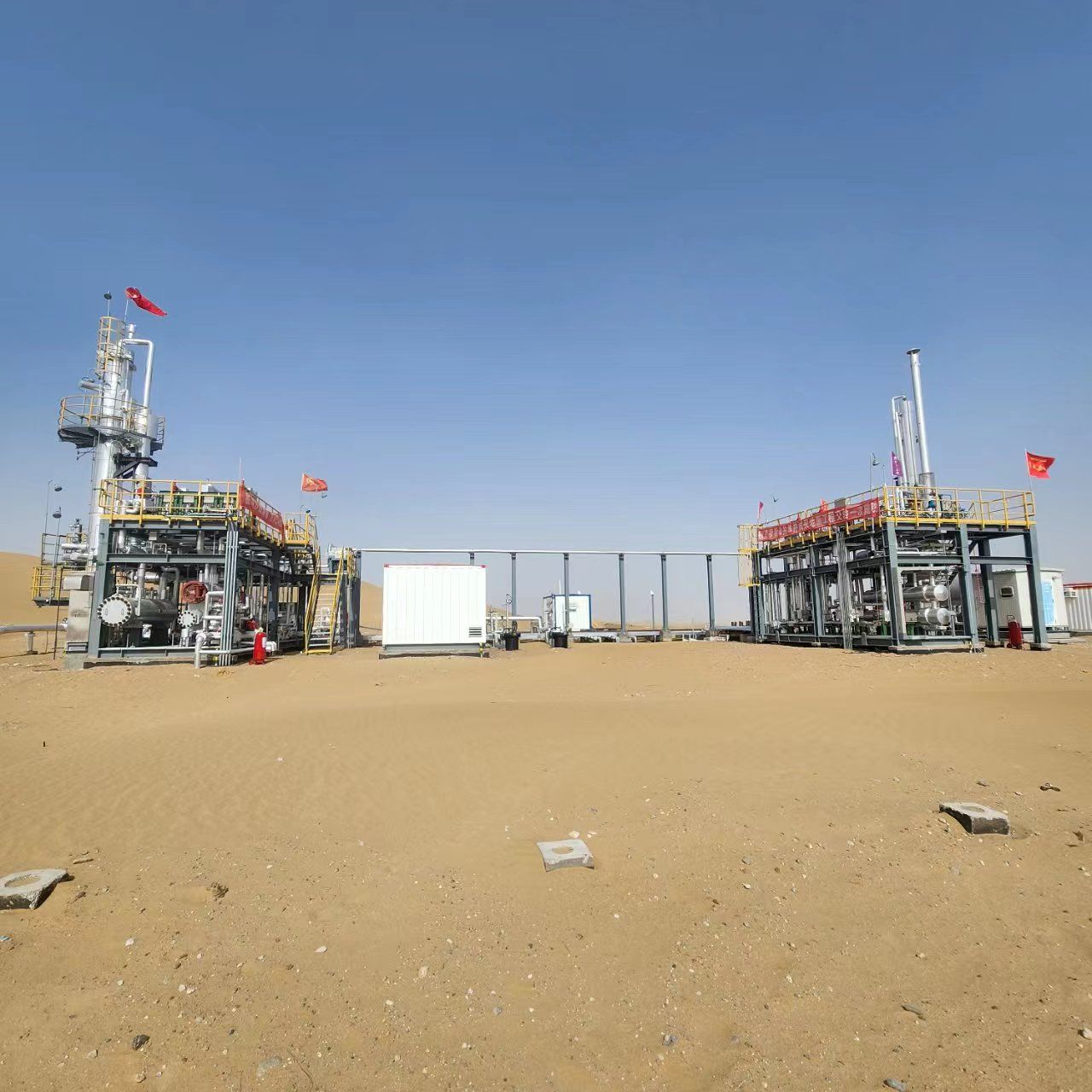

1.100×104 m3/d skid-mounted decarbonization plant for CNPC

The project is a model of high carbon natural gas treatment, and is also the model of Daqing oilfield which firstly implemented module skid mounted, designed & purchased in one year, and manufactured and went into operation in Northeast China.

It is also our exploration in promoting EPC project, and will also be an important turning point for the company to connect a link between the preceding and the following in the EPC engineering project.

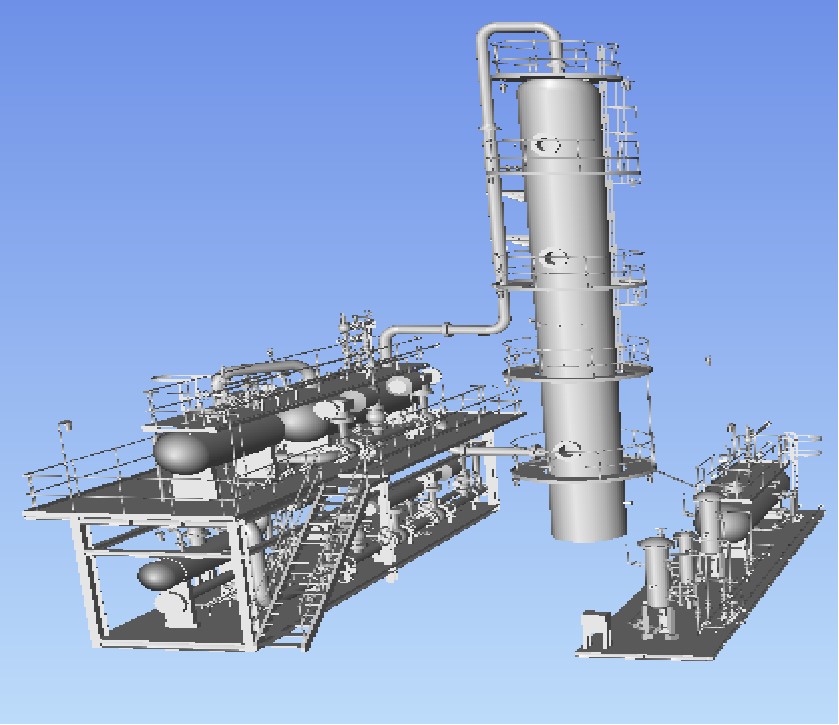

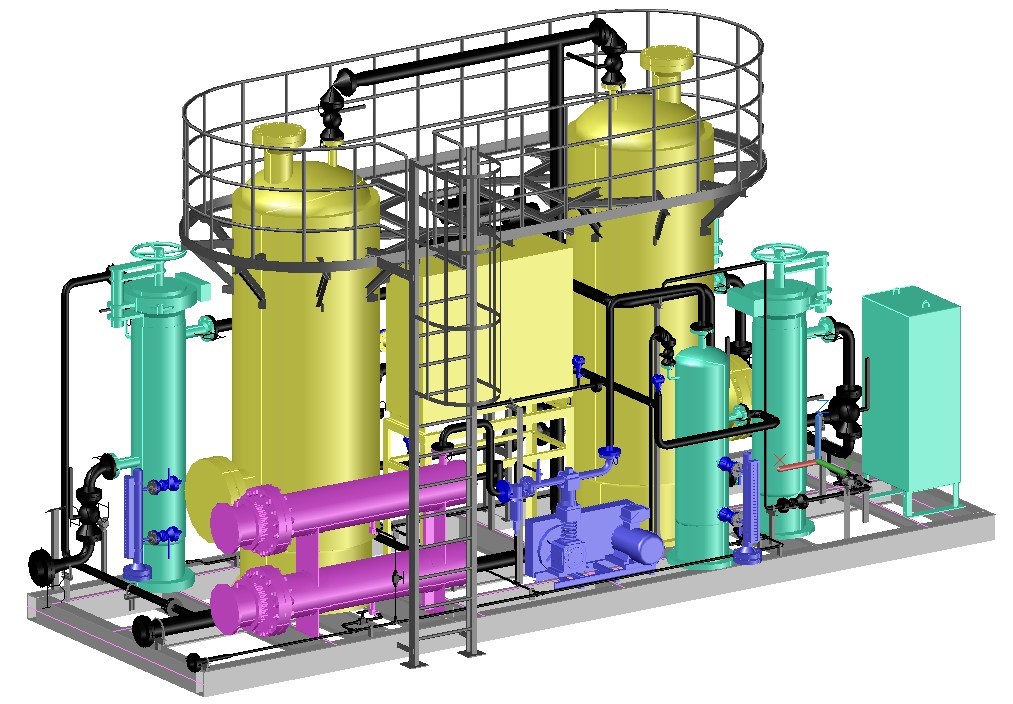

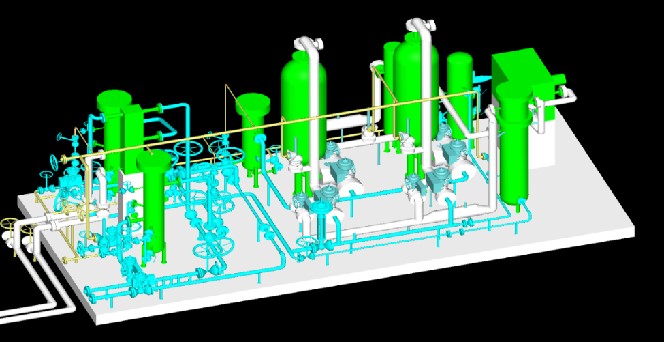

2. 300×104 m3/d desulfurization skid-mounted plant for CNPC

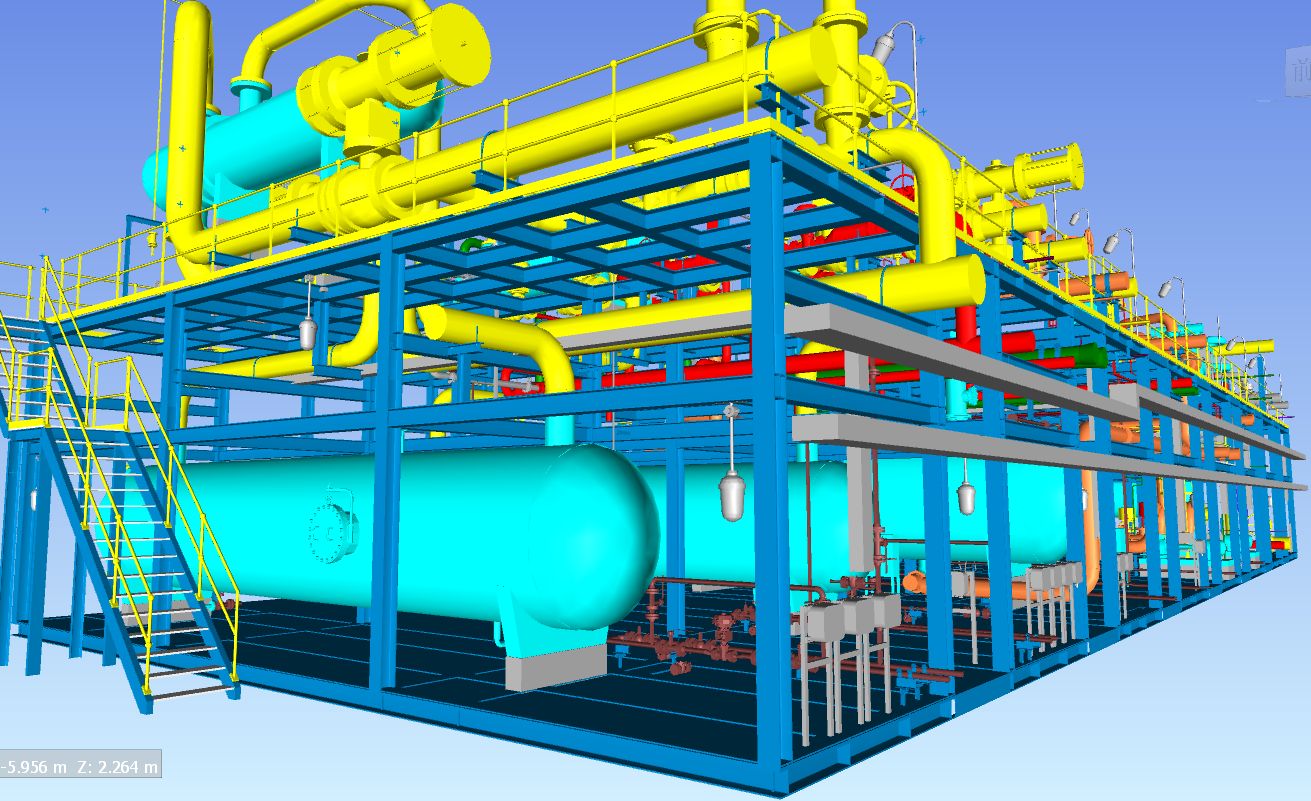

The natural gas, after flash evaporation from MDEA rich liquid, is removed H2S by acid water separator, and the separated MDEA solution is also pumped to the desulfurization tower.

The rich TEG solution used in dehydration tower goes into distillation tower, flash evaporation tank and filter and is heated and regenerated into lean TEG solution. Then it is pumped to the dehydration tower for circulating dehydration.

After the H2S gas separated by the acid water separator is injected into the acid gas storage tank, it is preheated by the reaction furnace, reacts with the air sucked in by the air compressor to generate SO2.

SO2 reacts with the remaining H2S (Claus reaction) to generate elemental sulfur, which is then cooled to obtain sulfur.

Feed gas,after its solid and liquid impurities are removed through separator and filter separator, enters the float valve tower for desulfurization, a tower which uses MDEA solution as desulfurizer.

The gas from the top of the float valve tower goes through the wet purification separator to remove a small amount of MDEA liquid entrained in the gas, and then the wet natural gas enters the dehydration tower to dehydrate through TEG.

At last, the dry natural gas from the dehydration tower is exported as qualified commercial gas.

The rich MDEA liquid in the desulfurization tower is flash evaporated to remove hydrocarbons and enter the filter for filtration. After that, it enters the regeneration tower and is heated by steam to regenerate into poor MDEA liquid, which is pumped to the desulfurization tower for circulating desulfurization.

3.Ya'an Zhonghong 10X 104 Nm3/d LNG liquefaction project

Construction site: Lushan County, Ya'an City, Sichuan Province,China.

The main technical parameters:

1. Processing capability

Input natural gas: 10X 10 4 Nm³/d

Liquefaction output: 9.53 X 10 4 Nm³/d

Vent sour gas: ~1635Nm³/d

2. LNG product specifications:

LNG output: 68t/d (161m³/d); equivalent to gas phase 9.53X 10 4 Nm³/d

Temperature: -161.4 ℃

Storage pressure: 15KPa

4. 150-300×104 m3/d TEG dehydration plant for CNPC

Our company constructed Wei 202 and 204 TEG dehydration plant with treatment capacity of 300×104 m3/d and Ning 201 TEG dehydration plant project with treatment capacity of 150 ×104 m3/d.

TEG dehydration plant process is typically used to treat wellhead sulfur-free natural gas or purified gas from alcohol amine process desulfurization plant. TEG dehydration unit is mainly composed of absorption system and regeneration system. The core equipment of the process is absorption tower. The dehydration process of natural gas is completed in the absorption tower, and the regeneration tower completes the regeneration of TEG rich liquid.

The feed natural gas enters from the bottom of the absorption tower, and countercurrently contact the TEG lean liquid which entering from the top into tower, then the dehydrated natural gas leaves from the top of the absorption tower, and the TEG rich liquid is discharged from the bottom of the tower.

Afterwards, the TEG rich liquid enters into the flash tank to flash out the dissolved hydrocarbon gases as possible as it can ,after being heated up through the discharge pipe of the condenser at the top of the regeneration tower. The liquid phase leaving the flash tank flows into the lean-rich liquid heat exchanger and buffer tank after being filtered by the filter, and then enters the regeneration tower after being further heated.

In the regeneration tower, the water in the TEG rich liquid is removed though being heated under low pressure and high temperature. The regenerated TEG lean liquid is cooled by the lean-rich liquid heat exchanger and pumped into the top of the absorption tower by the glycol pump for recycling.

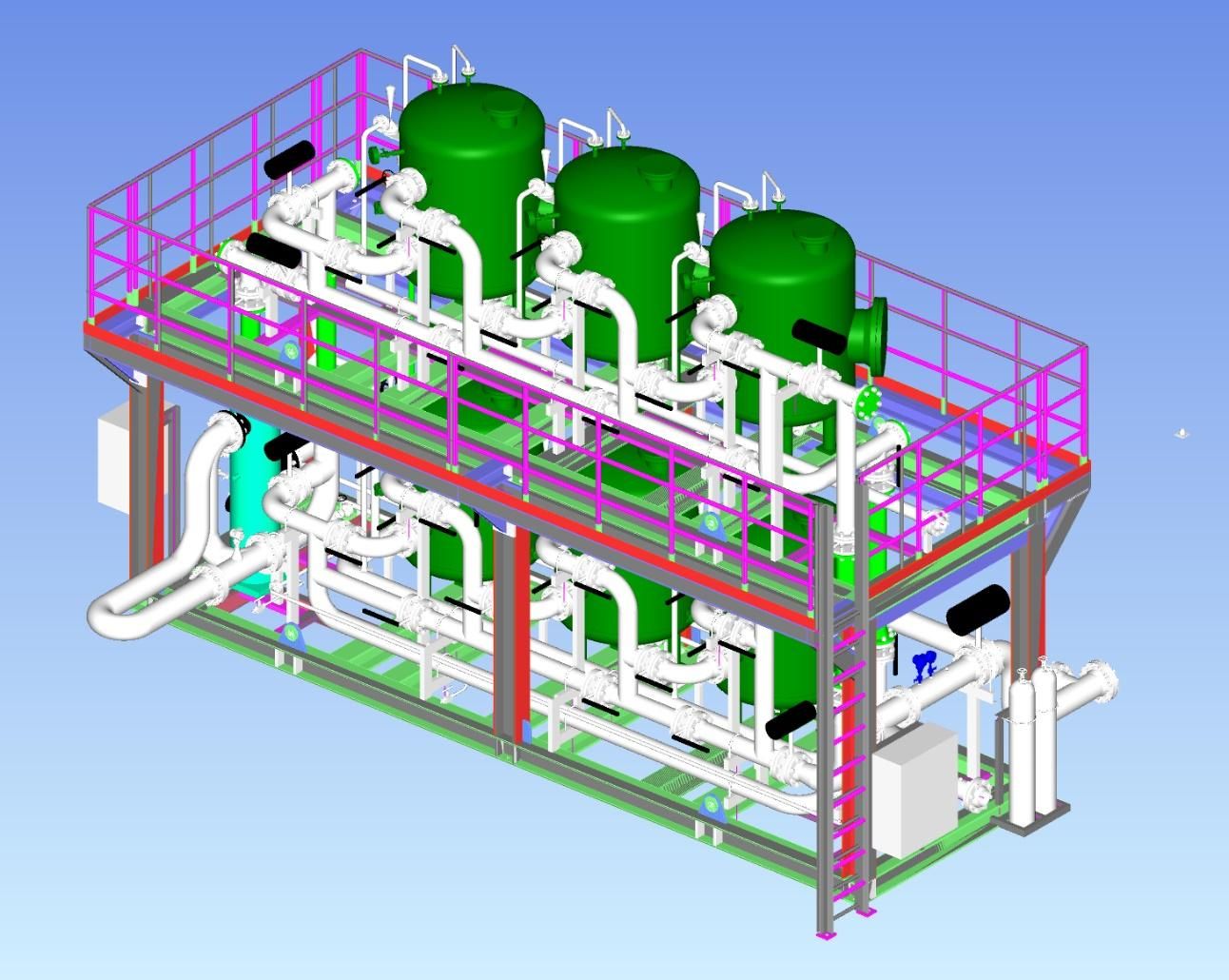

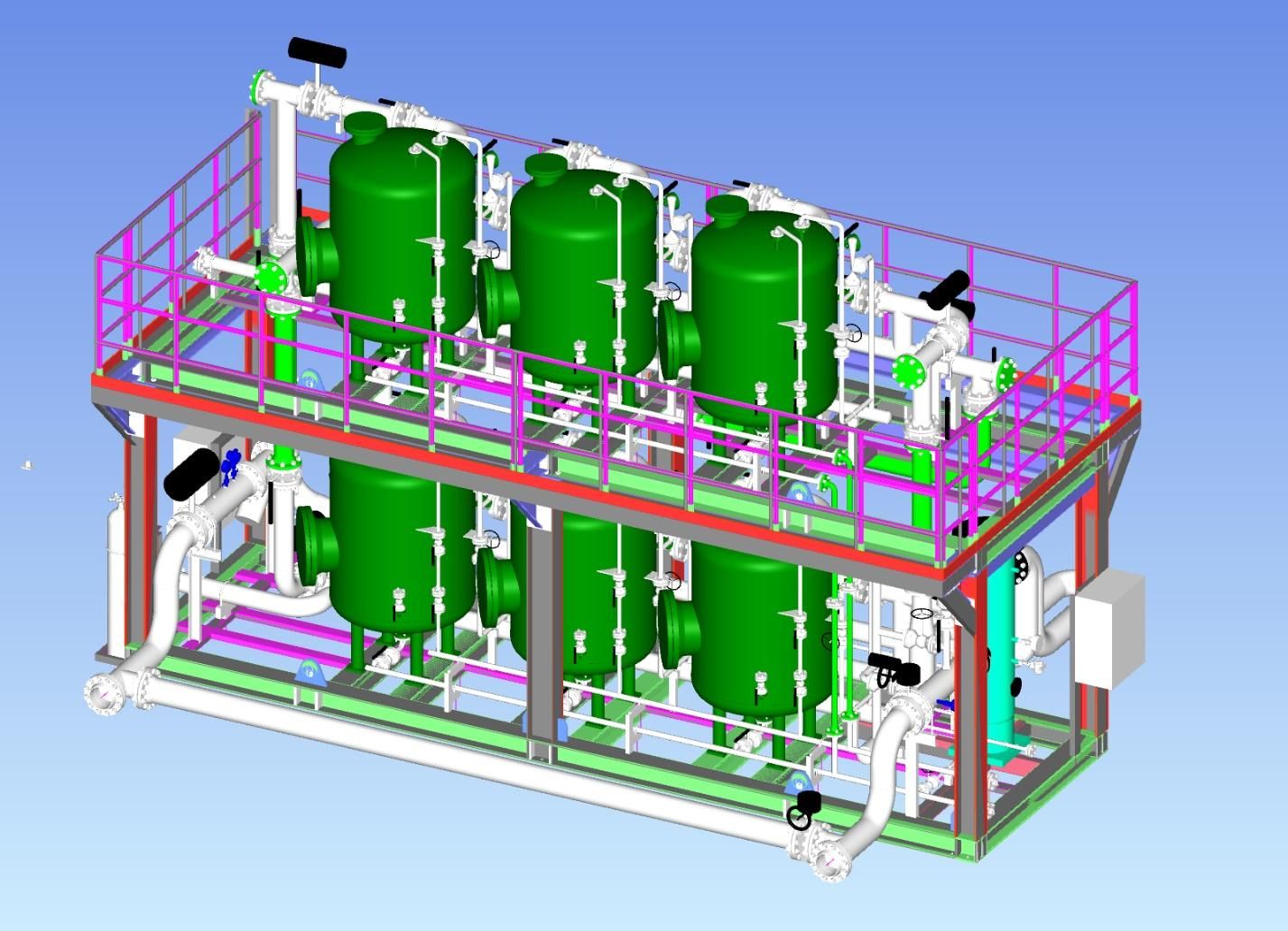

5. 30×104 m3/d molecular sieve dehydration plant for CNPC

Treatment capacity :14 ~ 29 × 10 m3/d

Working pressure: 3.25 ~ 3.65mpa (g)

Inlet temperature: 15 ~ 30℃

Water content of feed gas: 15-30°C saturated water

Design pressure: 4MPa

The feed gas of this project is the natural gas with high CO2 content from Lian 21 block and Lian 4 block in Fushan oilfield, Hainan province. In the early and middle stage of the pilot test, the produced gas from the two blocks was firstly made oil-gas separation in Bailian gas gathering station, next it was dried and dehydrated by molecular sieve dehydration skid, and then was pressurized to 14 to 22 MPa by gas injection compressor and injected into the ground.

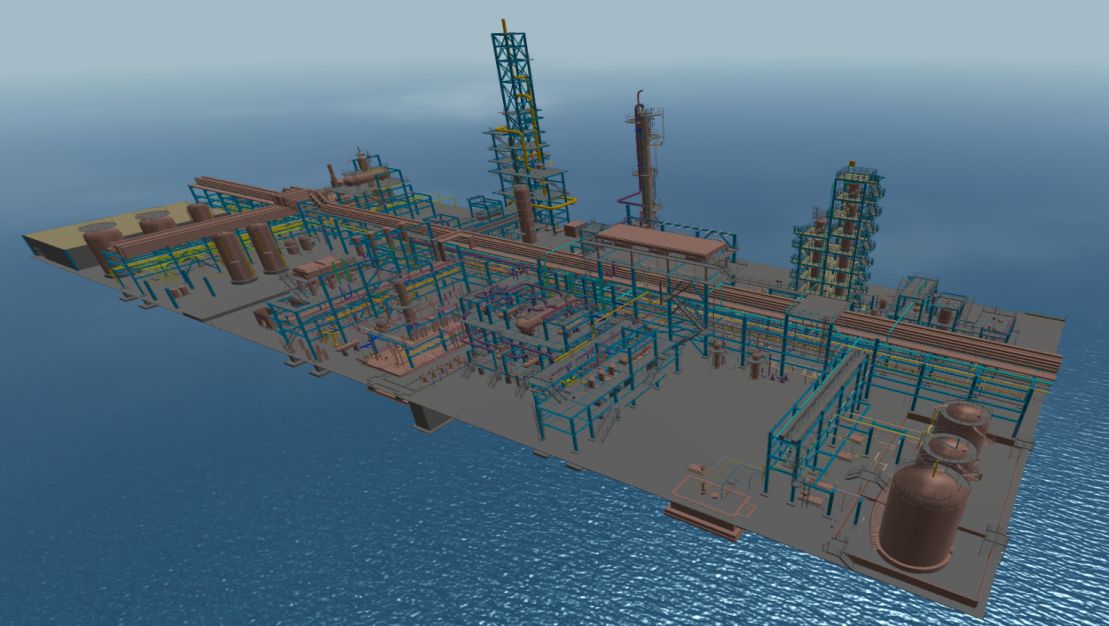

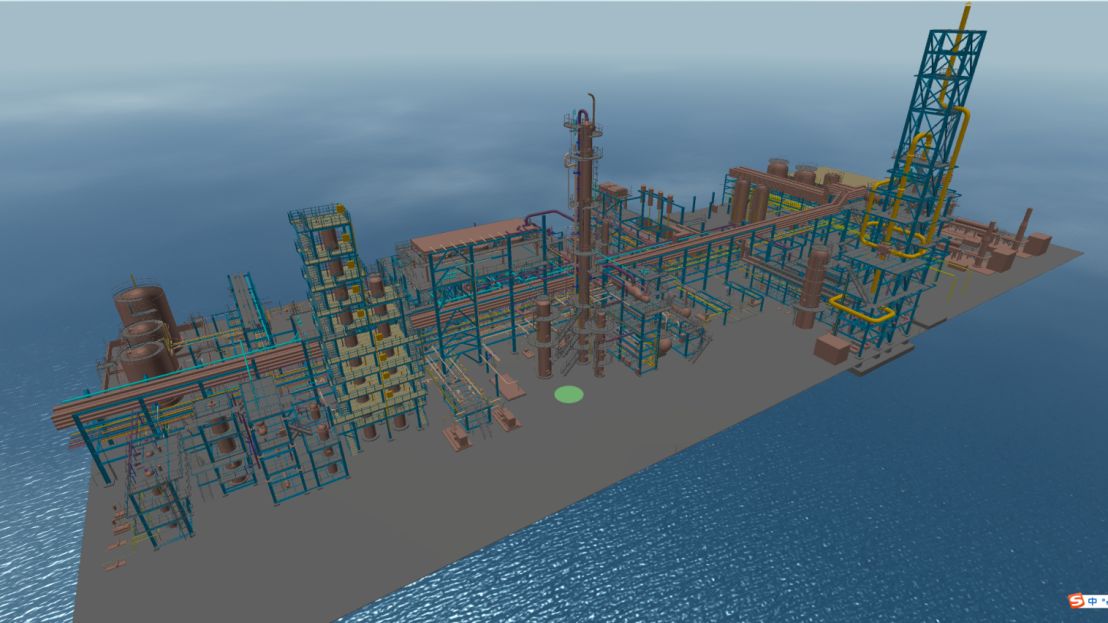

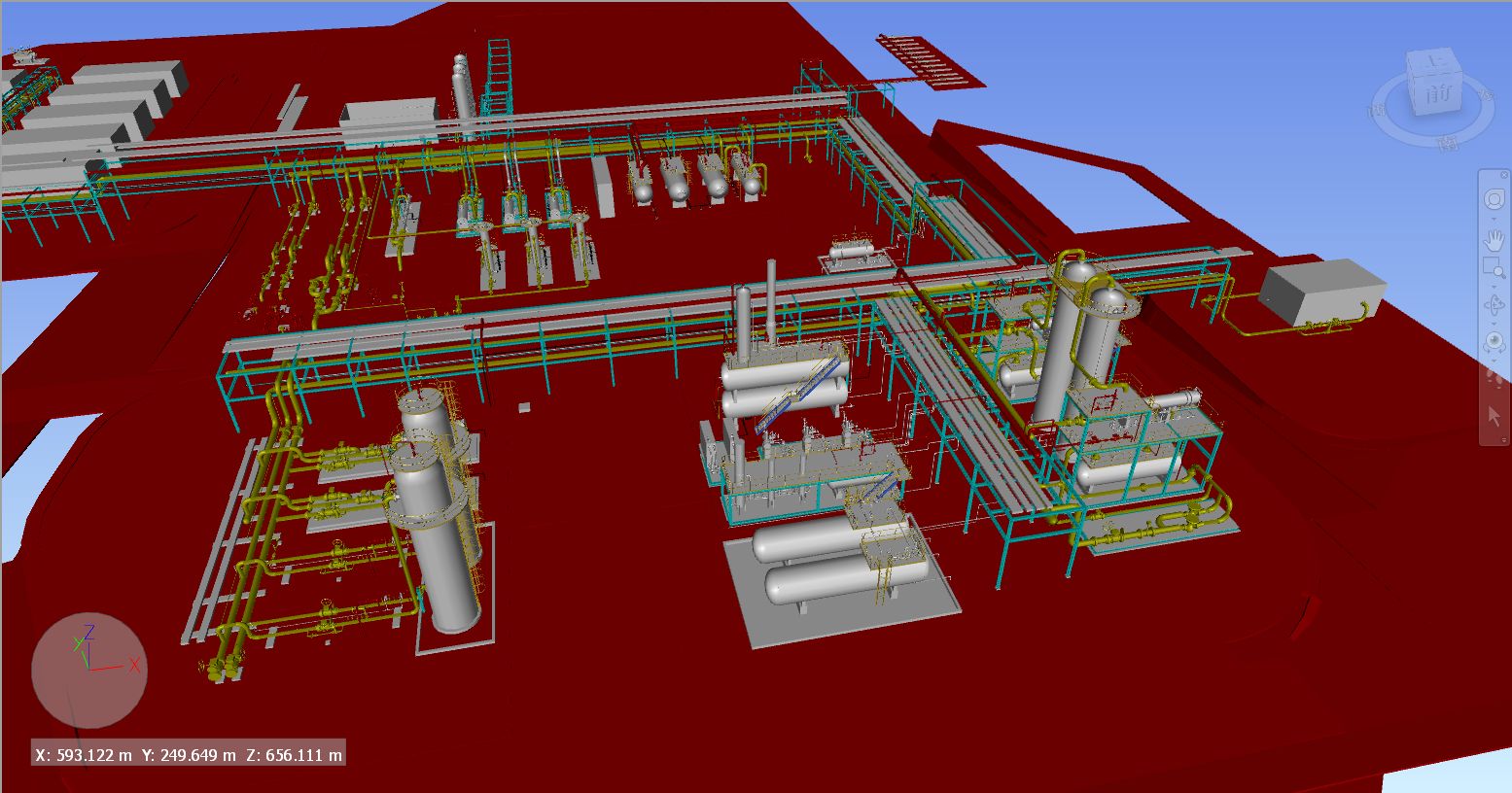

6. 100×104 m3/d LNG receiving plant for Qasim port, Pakistan

This project is designed and manufactured according to American Standard. LNG treatment plant and LNG transport ship delivere LNG to LNG gasification floating ship (storage and regasification unit) near FOTCO Wharf.

A new gas unloading wharf and pipeline will be built to transport the regasified natural gas from the LNG gasification floating ship to the connection point of SSGC, which is convenient for delivery to users in the future.

Construction site: Pakistan's second largest seaport, Rath Qasim seaport. It is located in the lower reaches of the Fitigli River, a branch of the west side of the Indus River Delta in the south of the country. Its northwest is about 13 nautical miles away from Karachi. It is the second largest seaport in Pakistan. It mainly serves for Karachi steel mills and domestic import and export goods, so as to reduce the pressure on Karachi Port.

Treatment capacity: 50 ~ 750 MMSCFD.

Design pressure: 1450 PSIG

Operating pressure: 943 ~ 1305 PSIG

Design temperature: -30 ~ 50 °C

Operating temperature: 20 ~ 26°C

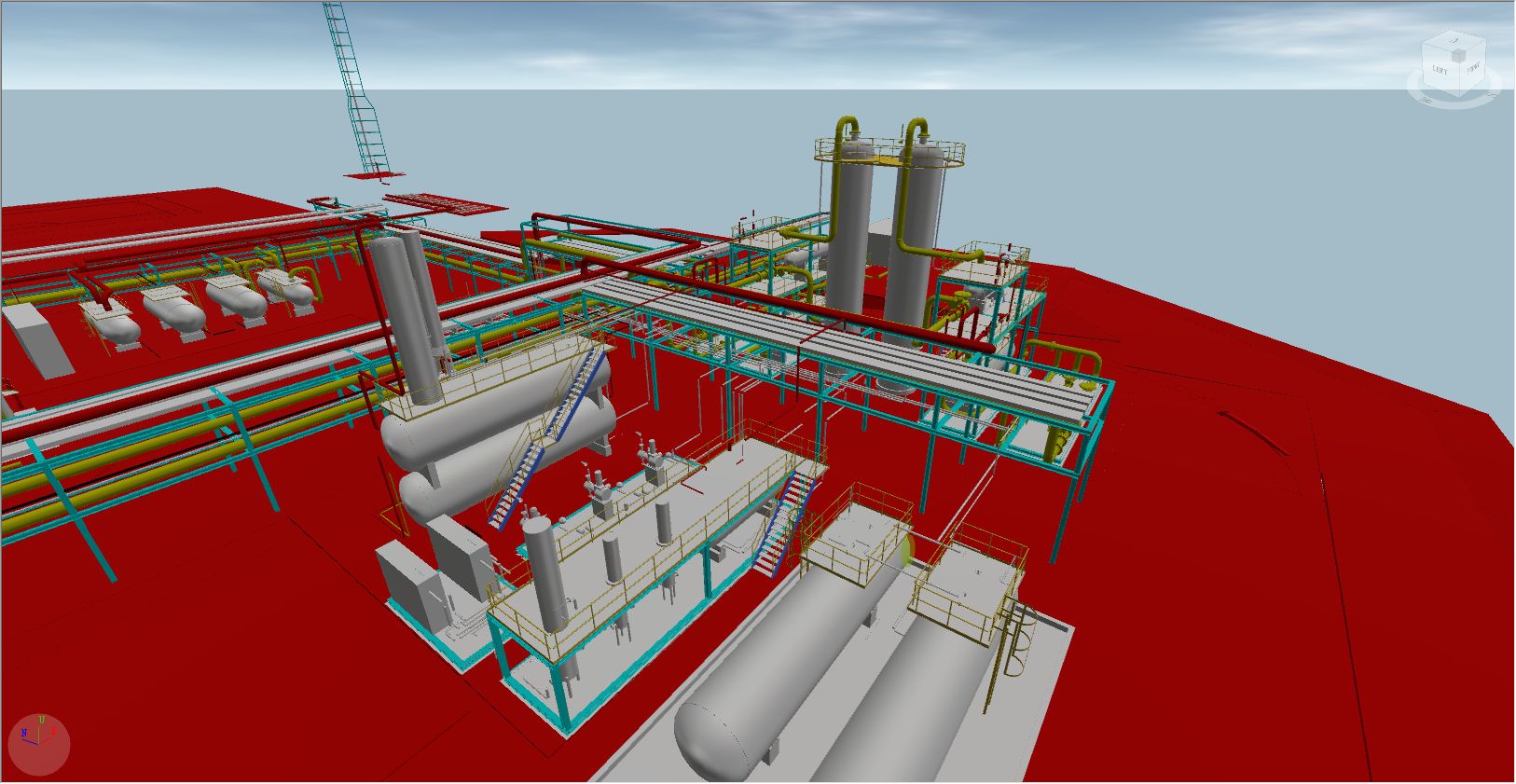

7. 50×104 m3/d LNG liquefaction plant in Datong city, Shanxi province

Shanxi Datong LNG project is one of the key projects of new energy in Shanxi Province and is a key project of gasification promotion in Shanxi Province. When the project is completed, the output will reach

As one of the peak reserve centers of Shanxi LNG, its output will reach 50x104 m3/d.

The project will build a 50×104 m3/d natural gas liquefaction project and supporting facilities and a 10000 m3 LNG full capacity tank. The main process units include feed gas pressurization, decarbonization unit, decarbonization unit, dehydration unit, mercury removal and weight removal, hydrocarbon unit, liquefaction unit, refrigerant storage, flash steam pressurization, LNG tank farm and loading facilities.

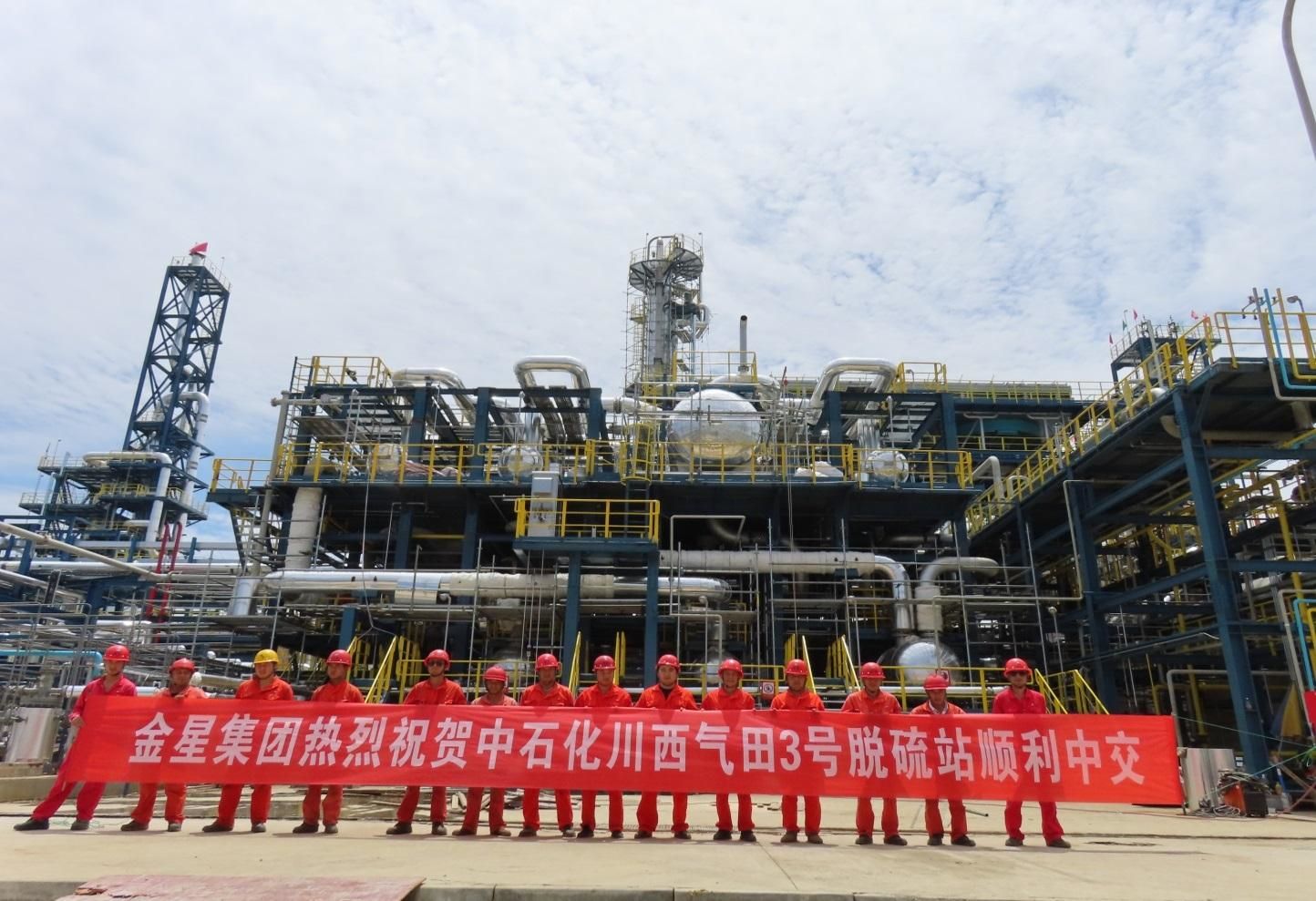

8. 30×104 m3/d desulphurization plant for CNPC

The supporting project of skid mounted desulfurization plant for marine gas wells in Western Sichuan Province,natural gas treatment skid,is the first project that our company cooperates with Sinopec Petroleum Engineering Design Co., Ltd.;

This project is the supporting project of natural gas desulfurization with 0.3 100×104 m3/d in Pengzhou 1 well, including natural gas processing skid, sulfur recovery and molding, public engineering and other units.

9.Ganquan Fengyuan 10X 104 Nm3/d LNG liquefaction unit

Construction site: Ganquan, Yan'an City, Shanxi Province,China.

The main technical parameters:

1. Processing capability

Inlet natural gas: 10X 10 4 Nm³/d

Liquefaction production: 9.48 X 10 4 Nm³/d (in storage tank)

Vent sour gas: ~5273Nm³/d

2. LNG product specification:

LNG output: 68.52t/d (160.9m³/d) ; equivalent to gas phase 9.48X 10 4 Nm³/d

Temperature: -160.7 ℃

Storage pressure: 0.2MPa.g

10. 600×104 m3/d tail gas treatment plant for CNPC

The project is a tail gas treatment unit with a design capacity of 600 ×104 m3/d in CNPC Gaomo purification plant. It is mainly used to treat Claus tail gas of sulfur recovery unit, as well as liquid sulfur pool waste gas of sulfur recovery unit and TEG waste gas of dehydration unit. The design treatment capacity of the unit is matched with sulfur recovery unit and dehydration unit. The plant adopts CANSOLV process approved by Shell company and the tail gas after treatment can reach the SO2 emission standard of 400mg/Nm3 (dry basis, 3vol% SO2).

11. 600×104 m3/d evaporation crystallization plant for CNPC

The plant adopts multi-effective evaporation and condensation method to treat saline water. The produced water treated by evaporation crystallization unit is reused as make-up water for circulating cooling water, or as other production water in the plant. Pollutants are separated out from the sewage in the form of crystalline salt. The feed of evaporation crystallization plant is saline water from upstream electrodialysis plant, and the treatment capacity of the plant is 300 m3/d. The annual production time is 8,000 hours.

The multi-effective evaporation is adopted to realize the stepwise utilization of energy and the energy saving effect is obvious.

The waste heat of the whole system is fully utilized. The evaporation crystallization unit only needs a small amount of high-grade heat energy to realize zero discharge of sewage from natural gas purification plant.

The treatment effect is good, and the treated water can meet the standard of circulating water, so it can be used as make-up water for circulating water.

The heat exchange tube is made of titanium material with good heat transfer efficiency. Other main equipment adopts 316L composite plate, which has stable operation, high degree of automation, simple operation and wide application range.

12.Tongguan 10X 104 Nm3/d LNG liquefaction unit

The main technical parameters:

1. Processing capability

Input natural gas: 10X 10 4 Nm³/d

Liquefaction production: 9.9X 10 4 Nm³/d (in storage tank)

Vent sour gas: ~850Nm³/d

2. LNG product specification:

LNG output: 74.5t/d (169.5m³/d) ; equivalent to gas phase 9.9X 10 4 Nm³/d

Temperature: -160.6 ℃

Storage pressure: 0.2MPa.g

13. 30×104 m3/d LNG liquefaction plant in Cangxi city

Invested by Cangxi Datong Natural Gas Investment Co., Ltd. With 170 million yuan, the project will construct 300×104 m3/d LNG liquefaction project and supporting facilities and a 5000 m3 LNG full capacity tank.

MRC refrigeration process is adopted, and the main process plants include raw material gas pressurization unit, decarburization unit and dehydration unit, mercury removal and heavy hydrocarbon removal unit, liquefaction unit, refrigerant storage, flash vapor pressurization,

LNG tank zone and loading facilities.

Capacity: 30×104 m3/d

Working pressure: 5.0 MPa (g)

Design pressure: 5.5 Mpa (g)

Storage tank: 5000m3 full capacity tank

Storage temperature: -162°C

Storage pressure: 15KPa

14. 20×104 m3/d LNG plant for Xinjiang Luhuan Energy Ltd, Xinjiang

The main process units include feed gas pressurization, decarbonization unit, dehydration unit, mercury and heavy hydrocarbon removal unit, liquefaction unit, refrigerant storage, flash steam pressurization, LNG tank area and loading facilities. The feed gas is pipeline gas of 200,000 m3 / day, and the storage tank is 2000 m3 single volume tank.

Main technical parameters:

1. Processing capacity

Feed natural gas: 22x104 Nm ³/ d

Liquefaction output: 20x104 Nm ³/ d

Vent acid gas: 1152 Nm ³/ d

Venting nitrogen: 14210 Nm ³/ d

2. LNG product specification:

LNG output: 150 t/d (340 Nm ³/ d)

Storage pressure: 0.2 Mpa.g

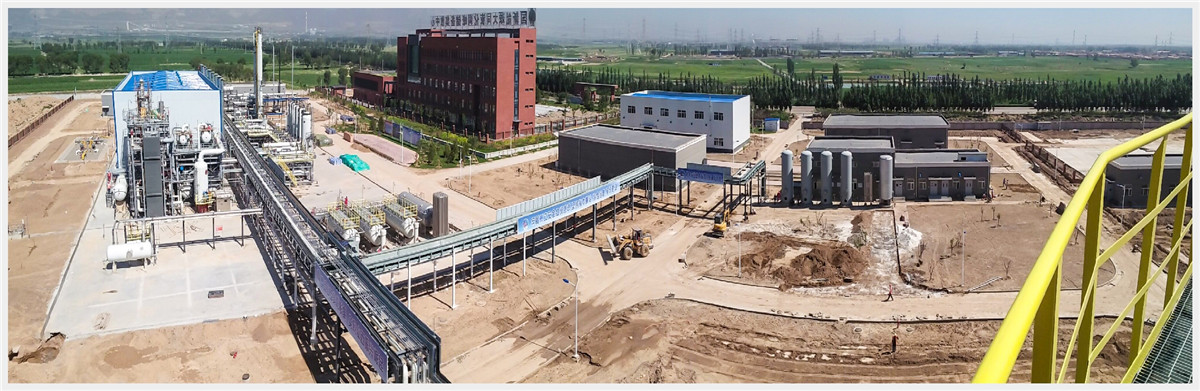

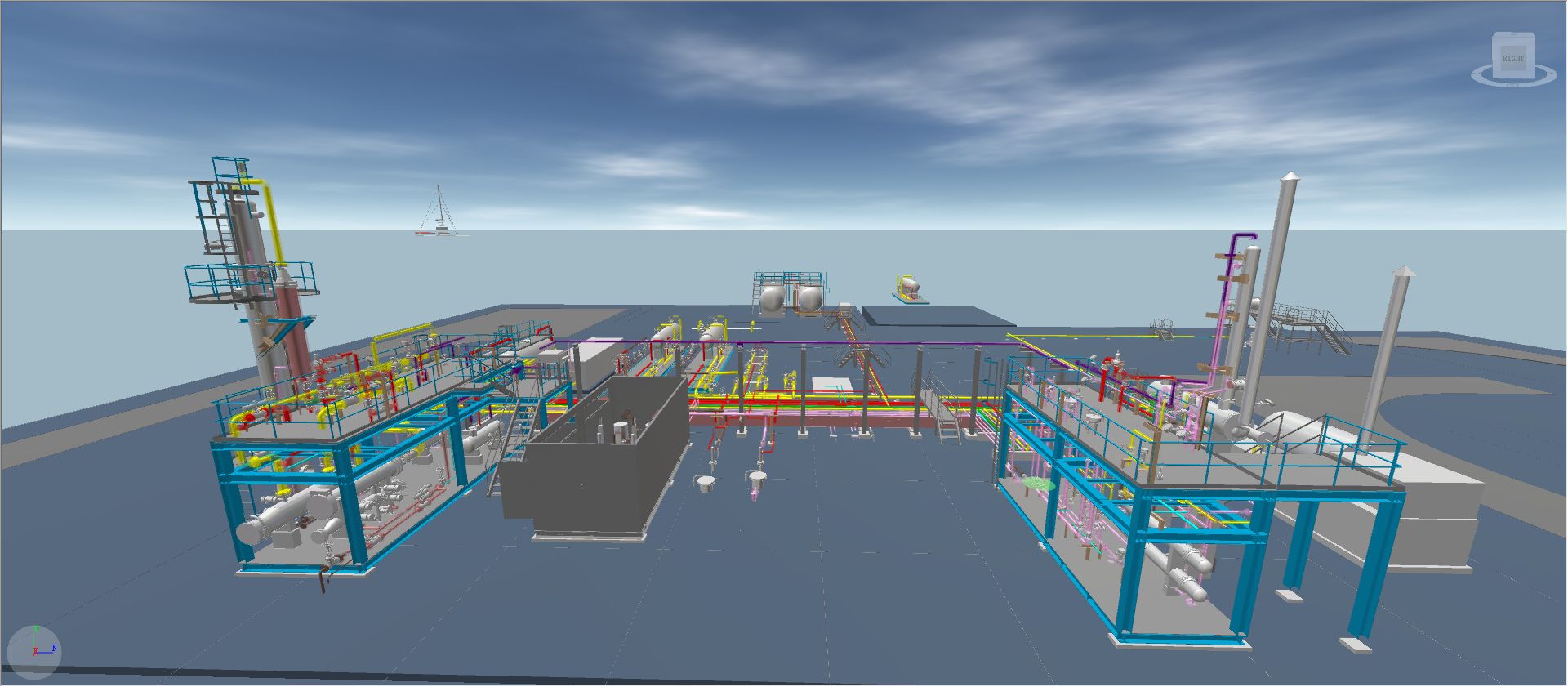

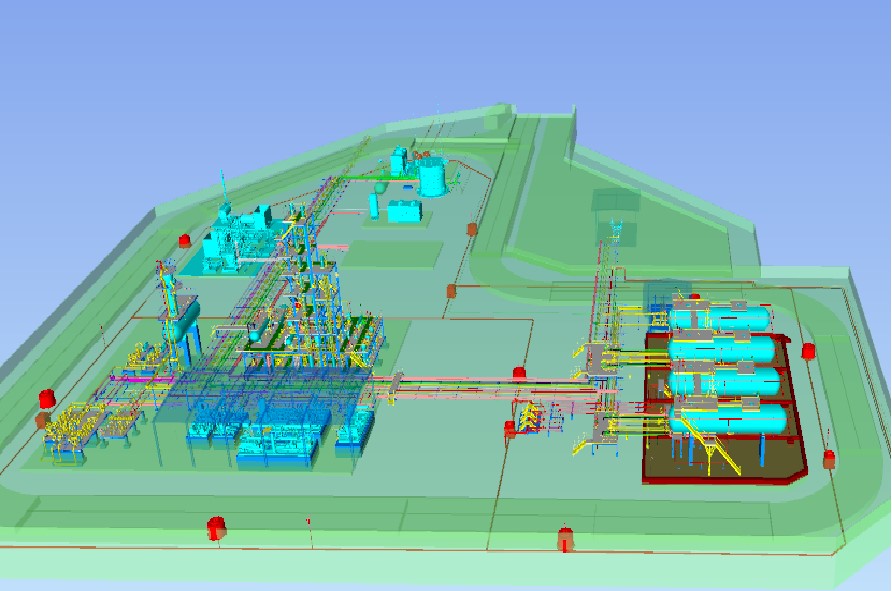

(15)4 million Nm3 deacidification package in Yanchang Oilfield

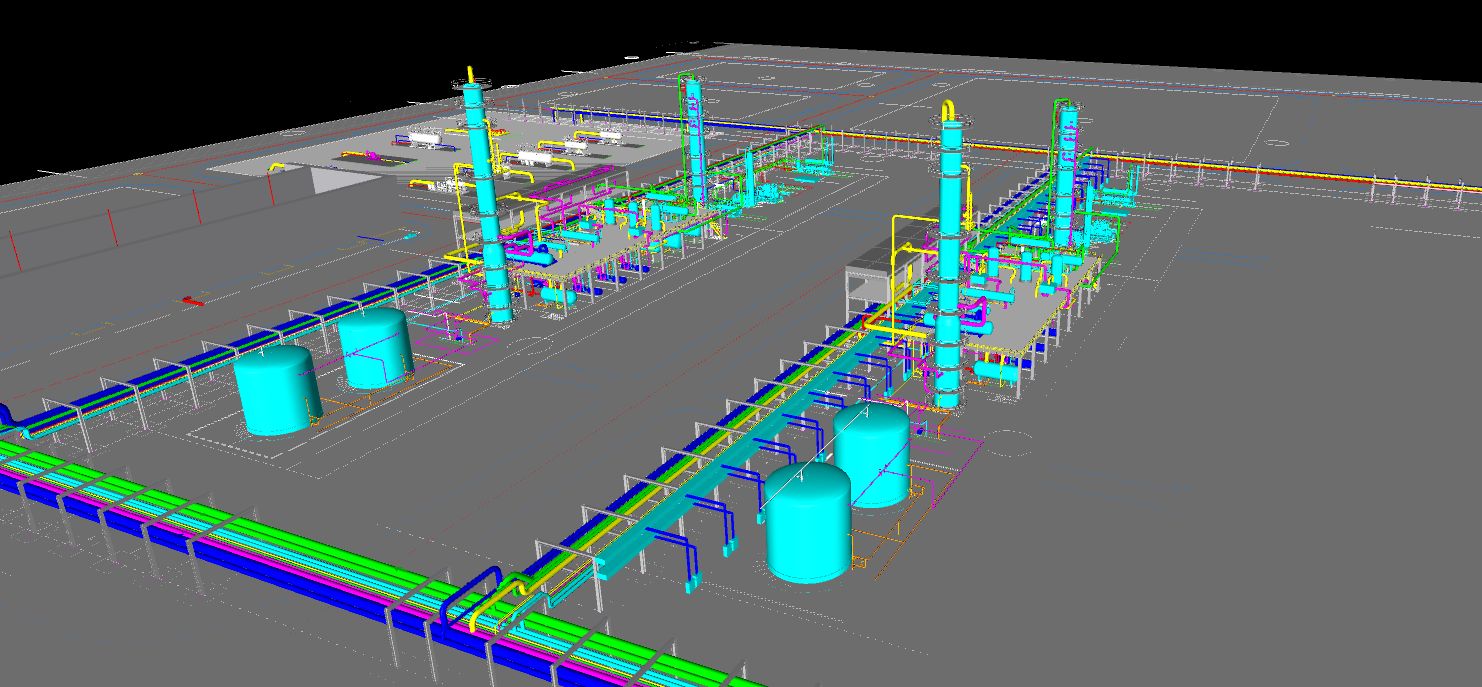

Yangqiaopan Purification Plant, with a total of 2 trains 4 millions Nm3/d deacidification and dehydration unit.

There are a total of 17 individual buildings, with a pipe gallery of approximately 1600m and a steel platform of 1260m2.

Operating pressure of raw gas: 4.9MPa DN350

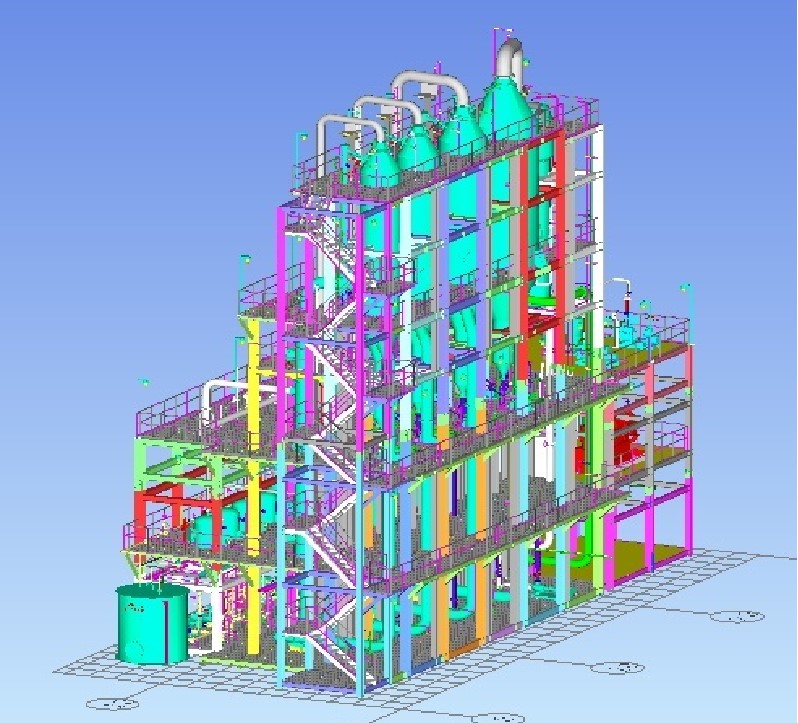

(16)500,000Nm3 Sulfur recovery unit and tail gas treatment project

The process of Claus flexible split flow sulfur recovery, partial oxidation+thermal incineration+alkaline flue gas desulfurization is adopted.

Project Name: Desulfurization Station of Leisi Gas Reservoir Capacity Construction Project in Xinchang Gas Field

Location: Deyang City, Sichuan Province

Construction unit: Southwest Oil and Gas Branch of China Petroleum and Chemical Corporation(SINO PEC)

(17)500,000Nm3 Sulfur recovery and tail gas treatment package

500,000Nm3 Sulfur recovery and tail gas treatment package

500,000Nm3 Sulfur recovery and tail gas treatment package

(18)40000Nm3/d associated gas desulfurization unit

Processing capacity: 40000 Nm3/day

Process: Complex iron desulfurization

The annual operating hours are calculated as 8000 hours.

Product Proposal

1) Associated gas outlet H2S ≤ 20mg/m3 (14ppm);

2) The removed H2S reaches the recoverable foam sulfur element;

(19)60,000Nm3/d gas desulfurization unit

Medium: Sour natural gas at the wellhead

Maximum H2S content: ≤ 10000 ppmv

Natural gas processing capacity: ≤ 2500 Nm3/h,

Inlet pressure: 0.2~1.3 MPa (g)

Design pressure: 1.5MPa (g)

Inlet temperature: 20-35 ℃

H2S content after treatment: ≤ 20 ppmv

60,000Nm3/d gas desulfurization unit

(20)300 million Nm3/d tail gas treatment package

1. Construction scale:

1 set of 300 million Nm3/d tail gas treatment unit is mainly used to treat Claus tail gas from the sulfur recovery unit.

Including oxidation unit (tail gas incineration and waste heat recovery system), CANSOLV pre washing system, CANSOLV absorption purification unit (including absorption section, regeneration section, and amine purification section).

2. The construction site is Zhongzhou Town, Zhongxian County, Chongqing City.

300 million Nm3/d tail gas treatment package

(21)120 million Nm3/d tail gas treatment package

Project: Jiulongshan Natural Gas Purification Plant

Design scale: 120 Nm3/d tail gas treatment device is mainly used to treat the Claus tail gas of the sulfur recovery unit, as well as the liquid sulfur pool waste gas of the sulfur recovery unit and the TEG waste gas of the dehydration unit.

After treatment, the tail gas can reach 400mg/Nm3.

The annual production time of the device is 8000 hours,

Operating flexibility:50% -120%.

Processing capacity:

Claus exhaust gas is 48.8132 kmol/h,

TEG exhaust gas is 2.2197 kmol/h,

Liquid sulfur pool exhaust gas is 0.7682 kmol/h.

120 million Nm3/d tail gas treatment package

(22)13.8million TEG dehydration unit

Project: Tongluoxia Gas Storage Construction Project

EP contractor: Tianjin Branch of China National Petroleum Pipeline Engineering Co., Ltd

TEG dehydration unit:

Processing capacity 13.8 million cubic meters/day

Design pressure/design temperature: 10MPa/55 ℃

Working conditions: 3.6~7.0MPa/15~34 ℃

(23)400,000Nm3/d TEG dehydration unit

Project Name: Surface Engineering for Single Well Trial Production of Ross 2 Well

Project location: Pishan County, Hotan Prefecture, Xinjiang Uygur Autonomous Region

Construction scale: The gas processing capacity is 400000m3/d.

The overall skid mounted natural gas TEG dehydration unit,

The dehydration of this project is used to treat natural gas under sulfur-containing conditions

(23)400,000Nm3/d TEG dehydration unit

(24)3 million Nm3/d TEG dehydration unit

Project Name: Gas Gathering and Dehydration Station Project in Heshen 4 Block of Hechuan Gas Field

Project location: Wusheng County, Sichuan Province

Construction scale: gas processing capacity of 3 million Nm3/d

Operating flexibility 50%~110%

Medium: Wet natural gas containing hydrogen sulfide,

Inlet: 3 million (101.325kPa, 20 ℃)natural gas,6.7~8.2MPa (g),Temperature 5-30 ℃

Outlet: Purified gas pressure 6.5~7.9MPa (g),Water dew point ≤ -5 ℃.

We provided the TEG dehydration unit for the below projects

Wei 202 Triethylene Glycol Dehydration Unit Project (with a processing capacity of 3 million cubic meters/day)

Wei 204 Triethylene Glycol Dehydration Unit Project (with a processing capacity of 3 million cubic meters/day)

Ning201 Triethylene Glycol Dehydration Unit Project (with a processing capacity of 1.5 million cubic meters/day)

(25)12 million Nm3/d LPG& NGL recovery package

Three oil extraction units are involved, and a total of four sets of original stable, light hydrocarbon, and mixed hydrocarbon units are planned to be constructed.

The construction sites are located in Jingbian County and Wuqi County, Shanxi Province.

The construction sites are located in Jingbian County and Wuqi County, Shanxi Province.

(26)2 million Light hydrocarbon recovery package

Project Name: Jiao 70 Natural Gas Dehydrocarbon and Capacity Enhancement Development Project

Project Name: Jiao 70 Natural Gas Dehydrocarbon and Capacity Enhancement Development Project

Construction scale:

The natural gas processing scale is 1.95million Nm3/d,

The stable light hydrocarbon reserve is 200m3,

The scale of natural gas pressurization is 1.95 million Nm3/d

2 million Light hydrocarbon recovery package

(27 ) Natural gas purification plant supporting evaporative crystallization device

Client: Chuanzhong Gas Mine, CPECC Location of use: Moxi Purification Plant, Gaomo Purification Plant Rated flow rate: 300×104Nm3/d Construction start date: April 5th, 2014 Project site completion date: July 25th, 2014.

(28) Gas molecular sieve dehydration unit

The raw gas for this project is high CO2 natural gas from Lian21 and Lian4 blocks in Fushan Oilfield, Hainan. In the early and middle stages of the pilot test, the produced gas from the two blocks in the Bailian gathering and transportation station is first separated from oil and gas, and then dried and dehydrated through a molecular sieve dehydration skid. Then, it is pressurized to 14-22MPa by a gas compressor and injected underground.

Client: CNPC Hainan Fushan Oilfield high CO2 natural

Processing capacity: 14~29×104m3/d

Working pressure: 3.25~3.65MPa (G)

Intake temperature: 15-30 ℃

Design pressure: 4MPa

(29) Molecular sieve dehydration and de-hydrocarbon removal device

We use a combination process of natural gas freezing and molecular sieve dehydration device. The design scale is 1.5×104m3/d, with a load variation range of 30%~100%. After dehydration, when the natural gas water dew point is pressurized to the maximum pressure of 2.5MPa in the station, it is 5 ℃ or more lower than the minimum transportation environment temperature (when the molecular sieve is activated, the water dew point is controlled at -5 ℃).

Client: PetroChina Gong108X Well

1)Feed natural gas inlet conditions: flow rate: 1.5×104m3/d,

Pressure: 1.6-2.5mpa. G,

Temperature: 5-39 ℃

2)Product gas conditions: flow rate: 0.7~1.5 × 104m3/d

Pressure: 1.5~2.4mpa. G

Temperature: 29 ℃

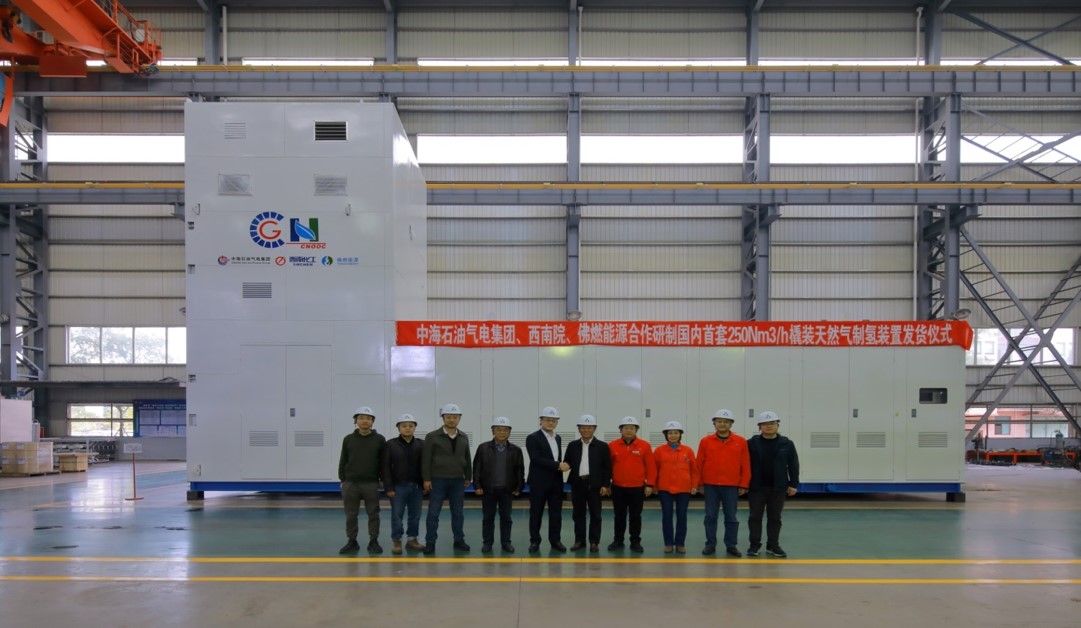

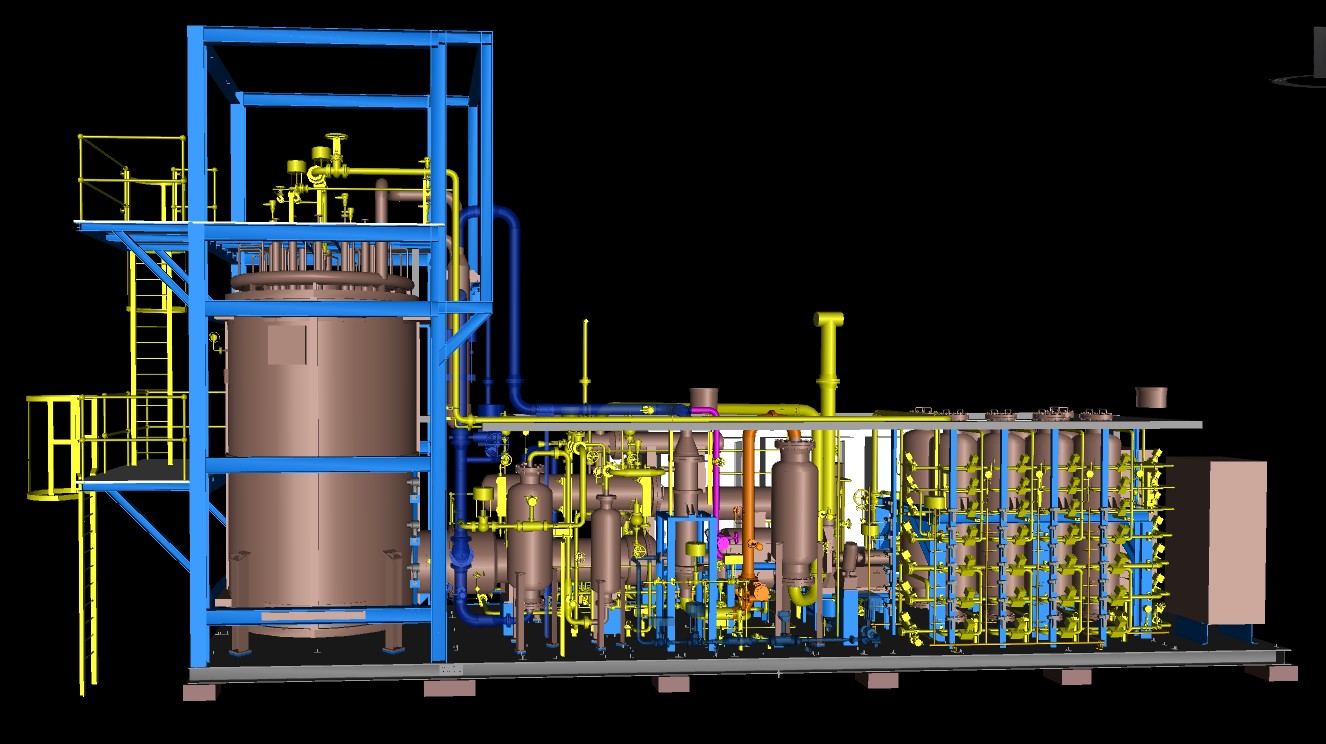

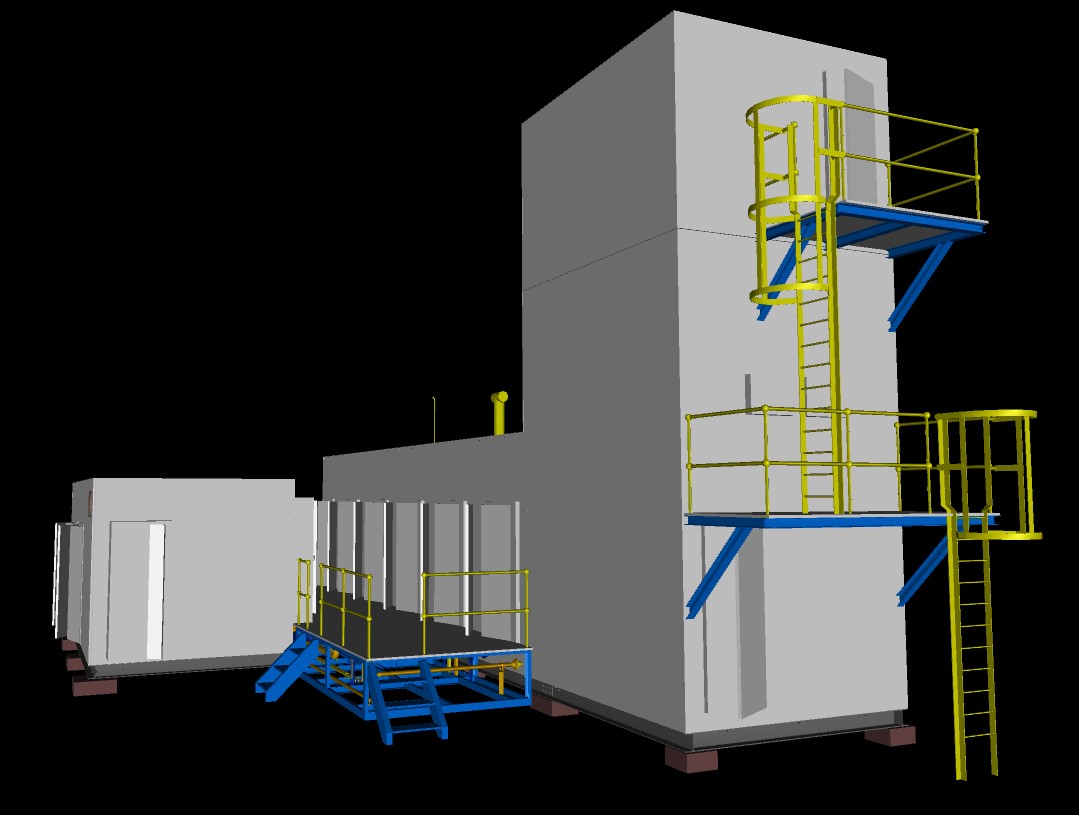

30)Hydrogen production from natural gas

250Nm3/h hydrogen production unit is the first project we have collaborated with CNOOC Southwest Chemical Institute on for natural gas hydrogen production; The project is located in Foshan, Guangdong.